- Since 2016

Innovation and research for dairy production

Mipp System builds state-of-the-art plants for the processing of dairy products, revolutionising the classic method

- Mipp quality

our patents and certifications

N. 102016000077298

- Mipp System

Superior technical and quality characteristics

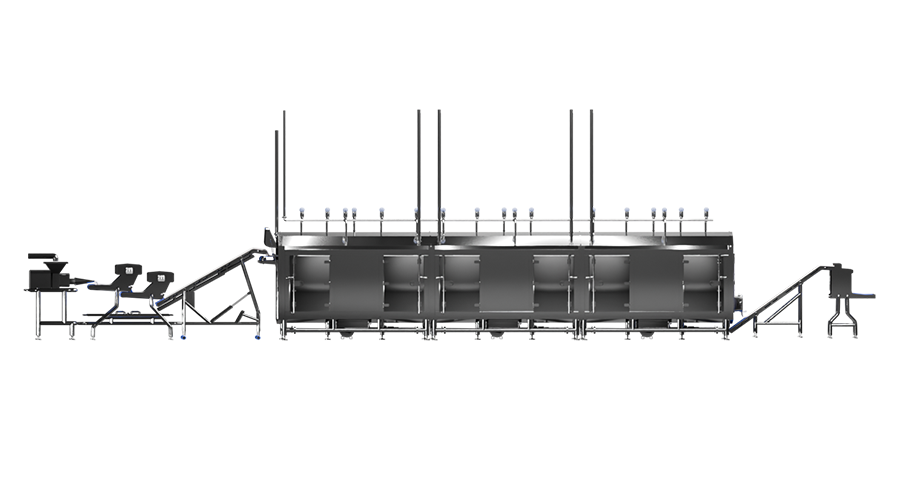

The heart of the Mipp System is designed in a modular way, allowing complete customisation according to the specific needs of the customer. This allows us to adapt the machine to production needs, making it versatile and easily scalable.

- Plus

PRODUCTION SPEED

The time drastically reduced from 150 minutes to 12–15 minutes.

Humidity control

Keeping the temperature positive helps guarantee the product’s consistency.

Energy saving

Our method allows a reduction in energy consumption of 20–30% compared to traditional methods.

Cooling with cold air

This eliminates the use of water and wastewater management, for a more eco-friendly approach.

Clean and precise cutting

The product is uniformly clean without cutting residues, this allows you to obtain even and perfectly shaped cubes.

- Mipp System

Cutting and shaping managed by PLC

- The customers

Mipp System around the world

With production facilities in different countries around the world, MippSystem is synonymous with innovation and reliability.

Our technologically advanced solutions are designed to optimise production processes, ensure maximum efficiency and significantly reduce energy consumption.

We support our clients internationally in achieving high standards of quality, productivity, and sustainability.

- UK

- Italy

- Spain

- Poland

- Netherlands

- Arab Countries

sustainability

Efficient, responsible and environmentally friendly food production

Our machinery for cooling dairy products is the result of years of research and development, designed to effectively address the sustainability challenges in the agri-food sector.

- METHOD

Mipp system green technology

The “Mipp” method, completely eliminates the cooling water, preventing the absorption of liquids by the product. This not only allows significant “energy” and “water” savings, but also eliminates the need to treat wastewater.