- Who we are

Our history, our mission: innovating the dairy sector

Mipp System Srl was founded with the ambitious goal of designing and manufacturing increasingly efficient systems for dairy product production, offering solutions tailored to various formats and meeting the demands of a constantly evolving market. From the beginning, our vision was clear: to create cutting-edge technologies that could significantly improve production efficiency, the quality of finished products and the reliability of industrial processes.

Our company is the result of an intense research and development process, started in 2016, which involved a team of engineers, food technologists and specialists in the sector. In recent years, we have worked with determination to analyse critical issues, identify innovative solutions and test new technologies capable of raising the quality standards of the dairy sector.

- Timeline

Origin of the idea

Model 1.0 is born

Model 2.0 is born

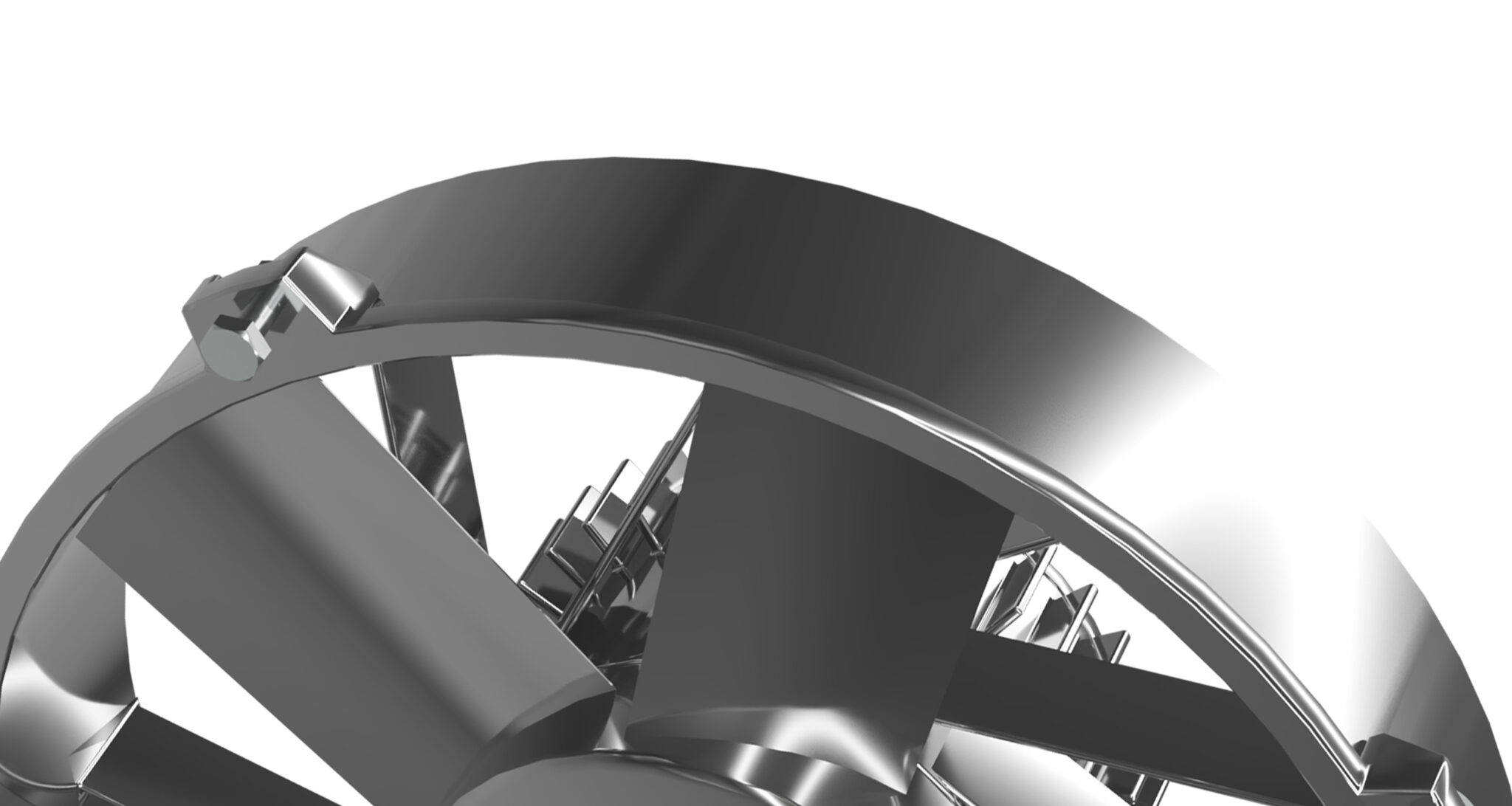

- The innovative MIPP system

After years of design, experimentation and continuous improvement, we have created an innovative system, which today represents a highly successful operational reality. Our systems not only guarantee the highest levels of efficiency and reliability, but are also designed to be modular, versatile and adaptable to the specific production needs of each customer.

Today, Mipp System Srl is synonymous with innovation, precision and passion for excellence in the dairy sector. Our commitment is focused on supporting producers in implementing more sustainable, efficient, and high-quality processes, with constant attention to technological advancements and new market challenges.

We are ready to continue our growth path, investing in research, the development of new solutions and the creation of solid partnerships with companies that, like us, believe in the value of innovation as a driver of progress.

The Patented Process

Mipp System Green Technology is a patented method that revolutionises the production of dairy products in individual portions, making the process not only more efficient, but also sustainable. One of the main features of this technology is the total elimination of cooling water by replacing it with air, further preventing bacteriological contamination of the product itself.