- The benefits

MIPP SYSTEM SRL HAS BEEN CONTINUOUSLY DEVELOPING AND RESEARCHING SINCE 2016

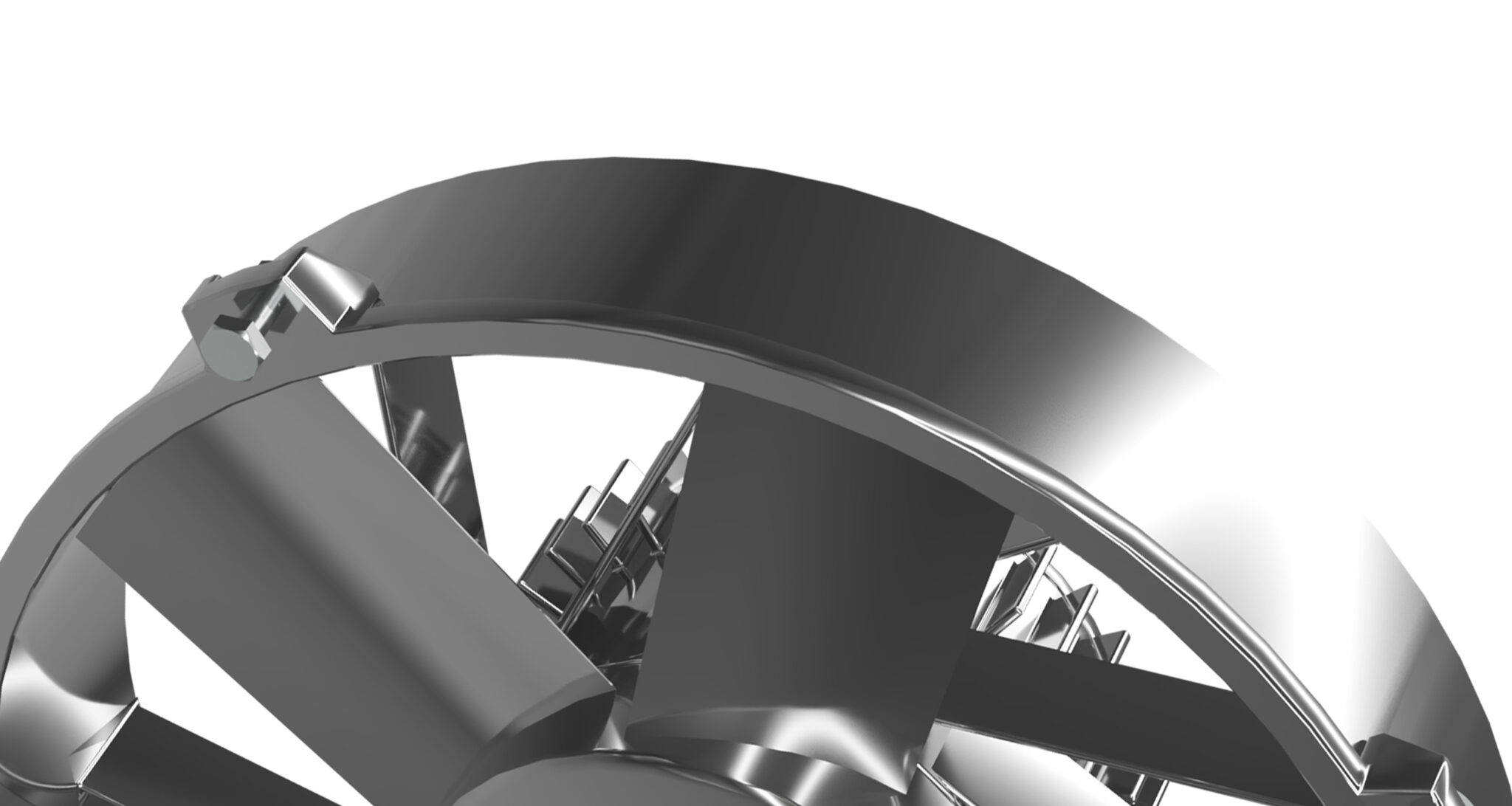

Mipp represents a highly efficient and versatile solution for the production of dairy products, optimising the process, reducing costs and environmental impact, and guaranteeing a final product of the highest quality.

Our strengths

Thanks to the efficiency of the control system and optimised process management, our method allows a reduction in energy consumption of 20–30% compared to traditional water cooling systems.

The time required for production is drastically reduced, going from 40 minutes (in which the product must be cooled and subsequently cut) to just “5–10 minutes”, with the product ready for cutting.

Thanks to its compactness, the Mipp System reduces space occupation by “50%”, going from a minimum of “150 m²” to only “70 m²”, optimising the use of production spaces.

The method is designed to operate continuously 24 hours a day, with short pauses for sanitisation every 3 to 4 days, ensuring high production efficiency without compromising on cleanliness.

The Mipp is designed to reduce “maintenance and sanitisation” costs, thanks to its advanced technology and the simplification of cleaning processes.

Maintaining a positive temperature during cooling reduces moisture formation and prevents frost buildup, keeping the final product in the best possible condition.

The method allows the use of the curd at any time, without the need for specific ageing periods, increasing both flexibility and speed in the production process.

The “Mipp” method allows for reduced labour compared to the traditional method, as it shifts from an indirect to a direct production cycle. This significantly shortens processing times and enables more precise control, and can also be managed by PLC systems remotely.

Mipp System uses cold air to cool dairy products, completely replacing the use of water. This approach is not only more environmentally friendly, but also eliminates the need to treat wastewater (both water and brine¸ before discharging it into the sewage system, reducing environmental impact and simplifying waste management)

The machine is also ideal for situations where water is a limited resource, as it does not require water for cooling. This makes Mipp a perfect solution for plants in areas with great water scarcity, helping to preserve this vital resource.

During processing, there is no leakage of liquids, which would otherwise be lost. This is made possible by the process absorbing the liquid during the stretching phase, ensuring a firmer final product with no loss of moisture.

The product is cut in an extremely clean way, avoiding the formation of residues or imperfections. This allows for the production of uniformly shaped, perfectly formed cubes, with an optimised yield. This allows you to obtain uniform and perfect shapes, without cutting powder.

Air cooling, by preventing the release of moisture and liquids, stops the product from clumping after cutting and prevents the formation of lumps. This ensures a uniform product, easily handled and ready for packaging.

- Sustainability

A concrete step towards a more sustainable future

At the heart of our technology is a clear vision: to make food production more efficient, responsible and environmentally friendly. Our product cooling machinery dairy is the result of years of research and development, designed to effectively address the sustainability challenges in the agri-food sector.